CALL US

+86-19518052336

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2024-04-12 Origin: Site

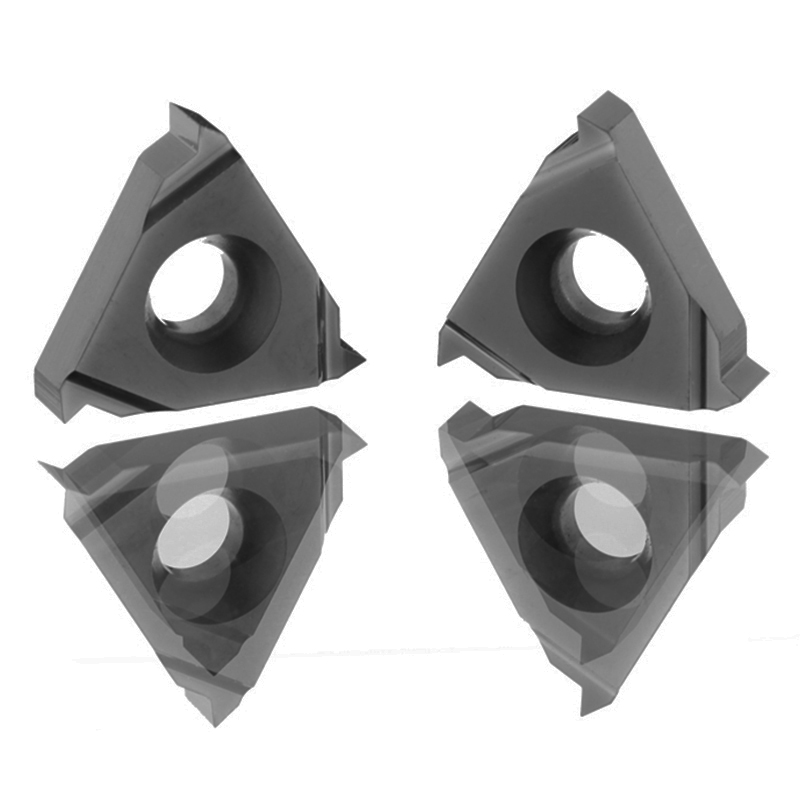

Metal processing industries, particularly in stainless steel and copper sectors, are undergoing a revolution with the introduction of indexable tungsten carbide inserts. These cutting-edge tools offer a wide range of advantages, from increased efficiency to cost savings, making them a game-changer in the field. In this article, we will explore the benefits of indexable tungsten carbide inserts and delve into their applications in both the stainless steel and copper industries. By understanding how these innovative inserts are transforming metal processing operations, companies can stay ahead of the competition and achieve greater success in their production processes.

Tungsten carbide inserts are widely recognized in the manufacturing industry for their numerous advantages. One of the key benefits of these indexable inserts is their exceptional hardness and durability, making them ideal for cutting, shaping, and forming various materials. The high wear resistance of tungsten carbide inserts ensures a longer tool life, ultimately leading to cost savings for businesses.

Additionally, the versatility of indexable tungsten carbide inserts allows for enhanced performance in a variety of machining applications. Whether it's turning, milling, or drilling, these inserts can provide precision and consistency in operations, resulting in high-quality finished products. The ability to maintain sharp cutting edges even under high-speed and high-temperature conditions further highlights the efficiency of tungsten carbide inserts.

Furthermore, the superior thermal conductivity of tungsten carbide inserts helps to dissipate heat during cutting processes, reducing the risk of thermal damage to workpieces and prolonging tool life. This thermal stability, combined with the inserts' resistance to corrosion and abrasion, makes them a reliable choice for demanding machining tasks.

The applications of stainless steel in the industry are vast and varied, with one of the key components being tungsten carbide inserts. These inserts are essential in enhancing the durability and strength of stainless steel products, making them ideal for use in a wide range of applications. From cutting tools to industrial machinery, tungsten carbide inserts play a crucial role in ensuring the quality and performance of stainless steel products.

One of the main advantages of using tungsten carbide inserts in the stainless steel industry is their exceptional hardness and wear resistance. This makes them perfect for cutting and shaping stainless steel, ensuring precision and efficiency in the manufacturing process. Additionally, tungsten carbide inserts can withstand high temperatures, making them ideal for use in extreme heat conditions commonly found in the industry.

Another key application of tungsten carbide inserts in the stainless steel industry is in the production of industrial machinery. These inserts are used in the manufacturing of various components, such as dies and molds, to ensure precise and accurate shaping of stainless steel products. Their high strength and resistance to wear make them essential for maintaining the quality and performance of industrial machinery in the industry.

The applications of tungsten carbide inserts in the copper industry are vast and crucial. These inserts are widely used in various processes such as cutting, drilling, and shaping copper materials. The superior hardness and wear resistance of tungsten carbide make it an ideal choice for these applications, ensuring efficiency and precision in production.

In cutting operations, tungsten carbide inserts are used to create clean and precise cuts on copper sheets and wires. The sharp edges of the inserts allow for smooth cutting without causing any deformation or damage to the material. This results in high-quality products with tight tolerances and smooth surfaces.

Drilling is another important application of tungsten carbide inserts in the copper industry. Whether it's creating holes for wiring or plumbing purposes, these inserts provide the necessary strength and durability to drill through copper materials effortlessly. The heat resistance of tungsten carbide also ensures that the inserts maintain their sharpness and efficiency during prolonged drilling operations.

Shaping copper components is yet another area where tungsten carbide inserts excel. Whether it's turning, milling, or grinding, these inserts can handle the high temperatures and pressures involved in shaping copper materials. This results in precise and accurate shaping, leading to the production of high-quality copper components for various industries.

Indexable tungsten carbide inserts offer manufacturers a competitive edge with their hardness, durability, and thermal conductivity, enhancing productivity and cost-effectiveness. In the stainless steel industry, these inserts are crucial for improving durability, strength, and performance of products due to their exceptional properties. Similarly, in the copper industry, tungsten carbide inserts play a vital role in ensuring efficiency, precision, and quality in production processes, contributing to the industry's advancement. Overall, these inserts are indispensable tools in machining, cutting, drilling, and shaping various materials, making them essential components in evolving industries.

+86-19518052336

333 Liantang Road, Cidong Binhai Development Zone, Longshan Town, Cixi, Ningbo City, Zhejiang Province, China