CALL US

+86-19518052336

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2024-04-20 Origin: Site

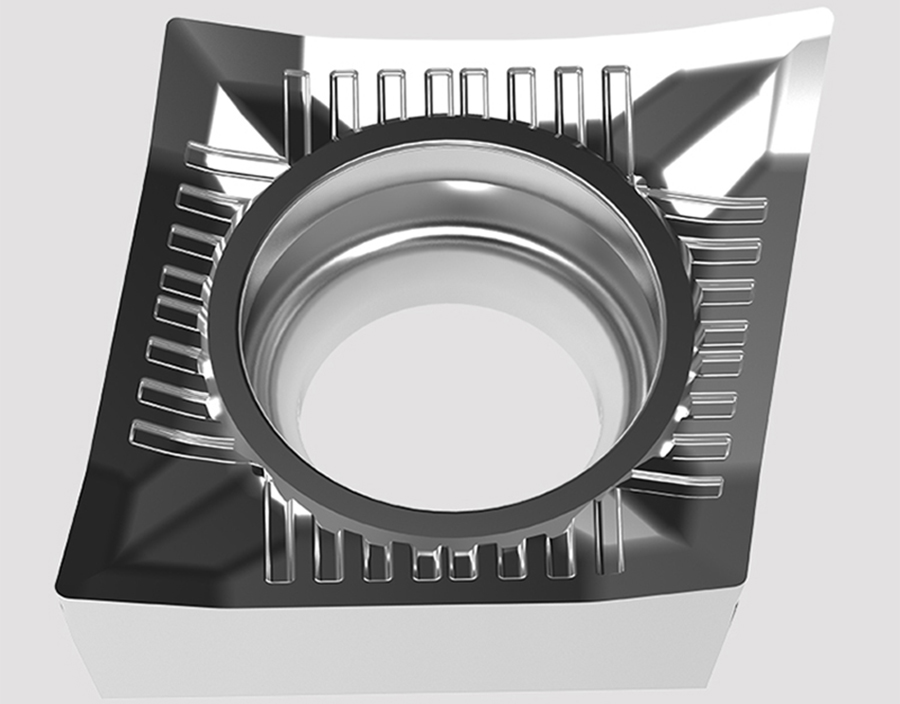

Tungsten carbide milling inserts have revolutionized the steel and aluminum processing industry, offering a range of benefits that have transformed the way manufacturers approach machining. From improved efficiency to enhanced durability, these inserts have become essential tools for achieving precision and quality in metalworking. In this article, we will explore the various advantages of using tungsten carbide milling inserts, as well as the diverse applications where they excel. Whether you are looking to increase productivity, reduce downtime, or achieve superior surface finishes, understanding the transformative power of these inserts is crucial for staying competitive in today's competitive manufacturing landscape.

Tungsten carbide milling inserts offer a wide range of benefits for those in the machining industry. These inserts are known for their exceptional hardness and wear resistance, making them ideal for cutting and shaping tough materials like steel, iron, and other alloys. One of the key advantages of tungsten carbide inserts is their longevity, as they can last much longer than traditional cutting tools, saving both time and money in the long run.

Another benefit of using tungsten carbide inserts is their ability to maintain a sharp cutting edge even under high-speed machining conditions. This results in improved surface finish and dimensional accuracy, leading to higher quality end products. Additionally, the high thermal conductivity of tungsten carbide helps dissipate heat during the machining process, reducing the risk of tool damage and prolonging tool life.

In addition to their durability and performance, tungsten carbide inserts are also highly versatile and can be used in a variety of machining applications, including milling, turning, and drilling. Their ability to withstand high temperatures and extreme pressures makes them suitable for a wide range of industries, from automotive and aerospace to tool and die making.

Tungsten carbide milling inserts are essential tools in the manufacturing industry, used for a wide range of applications. These inserts are made from a combination of tungsten and carbon, creating a durable and strong material that is perfect for cutting and shaping hard materials like steel, stainless steel, and cast iron.

One of the main applications of tungsten carbide milling inserts is in the machining of metal components. These inserts are used in milling machines to accurately cut and shape metal parts with precision. The hardness and wear resistance of tungsten carbide make it ideal for this application, ensuring that the inserts maintain their sharpness and cutting edge for a long time.

Another common application of tungsten carbide inserts is in the woodworking industry. These inserts are used in woodworking tools such as saw blades and router bits to create clean cuts in hardwoods and other tough materials. The toughness of tungsten carbide allows for smooth and efficient cutting, making it a popular choice among woodworkers.

Additionally, tungsten carbide milling inserts are also used in the automotive industry for machining engine parts and other components. The high heat resistance of tungsten carbide makes it suitable for cutting and shaping materials at high speeds, ensuring efficient and precise manufacturing processes.

Tungsten carbide milling inserts offer machinists a valuable tool to enhance efficiency, quality, and productivity. These inserts stand out for their wear resistance, sharp cutting edges, and versatility, making them a smart investment for machining needs. They are suitable for a variety of industries such as metalworking, woodworking, and automotive, providing the durability, hardness, and precision required for efficient processes. Overall, tungsten carbide milling inserts are versatile assets that can significantly benefit manufacturing applications.

+86-19518052336

333 Liantang Road, Cidong Binhai Development Zone, Longshan Town, Cixi, Ningbo City, Zhejiang Province, China