English

EnglishCALL US

+86-19518052336

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

C08K-SDUCR07

SANDHOG

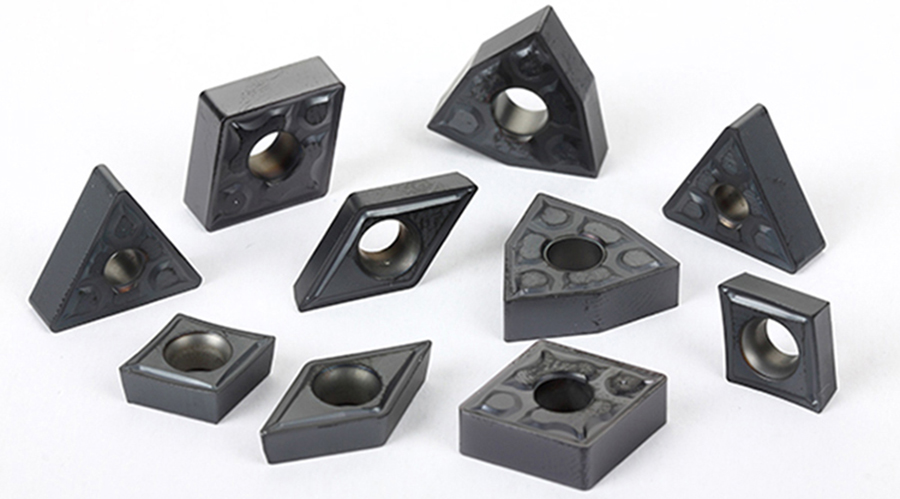

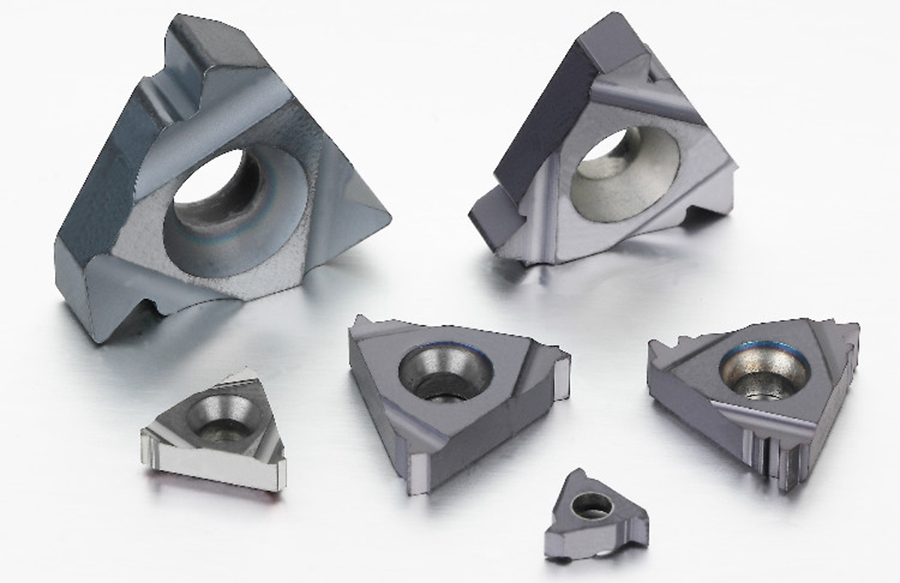

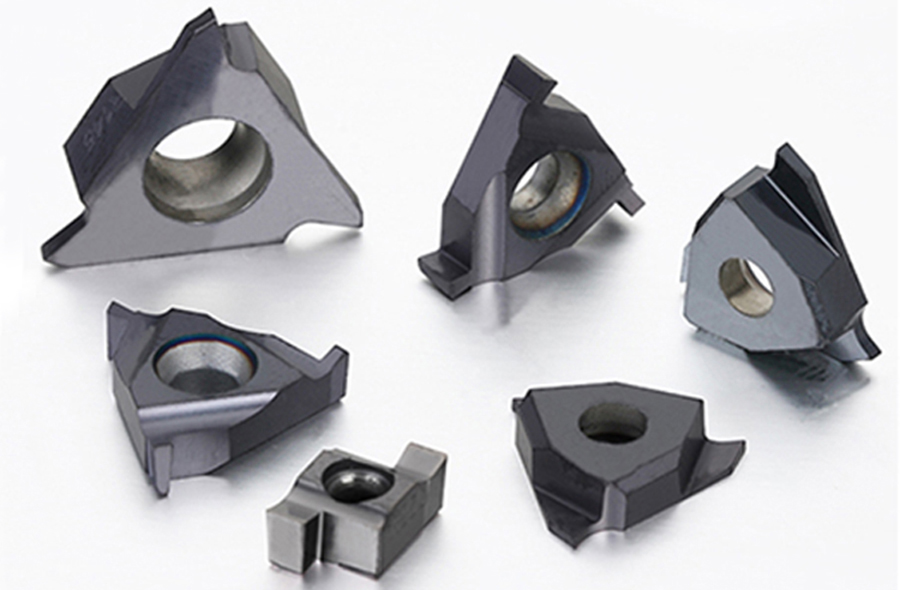

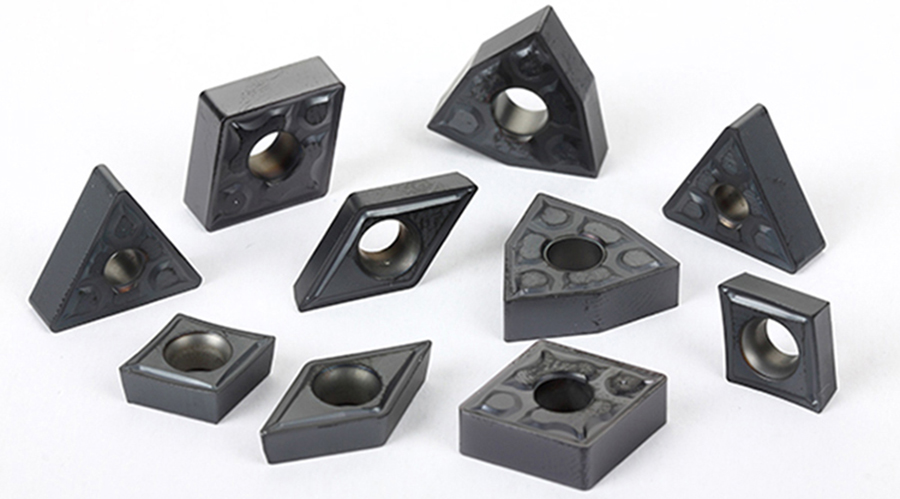

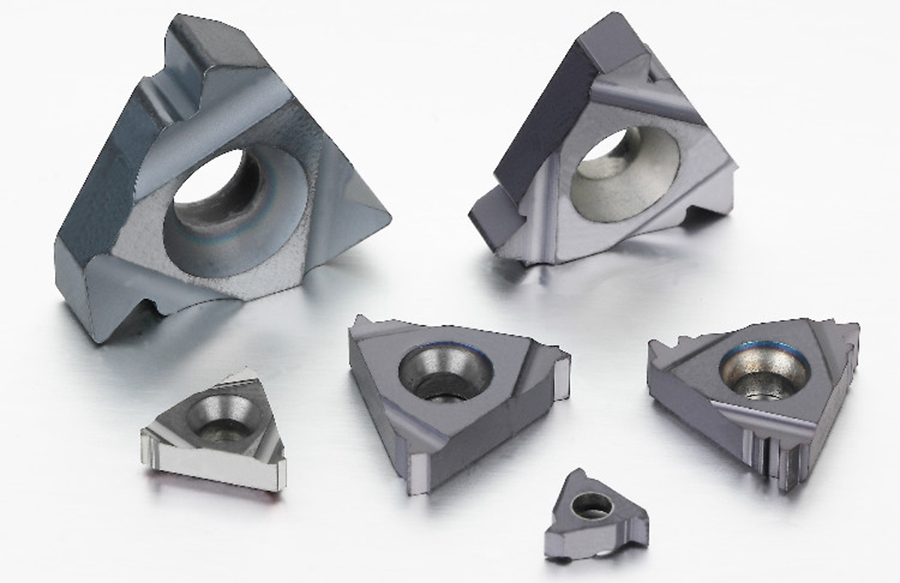

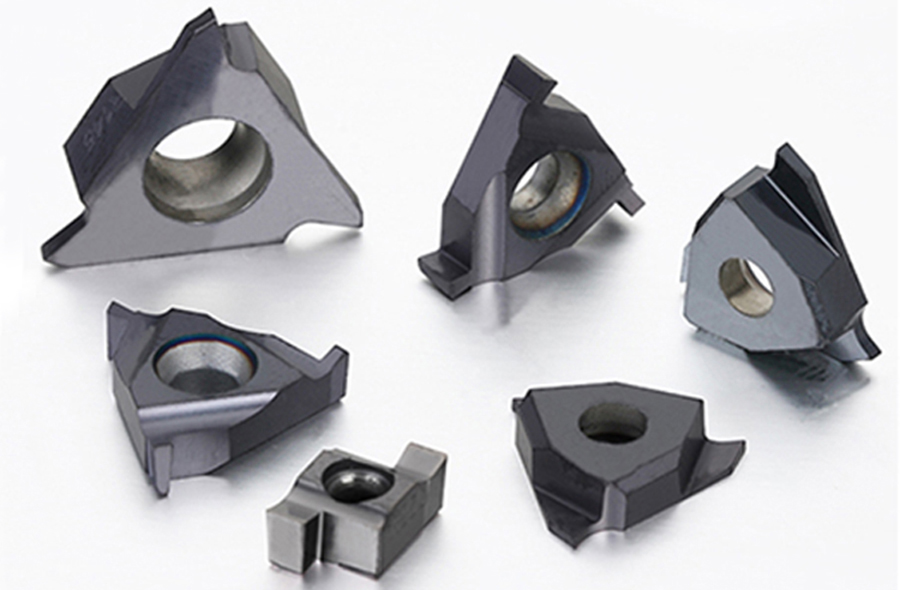

Ningbo SANHAN Alloy Material Co., Ltd. with years of experience in manufacture Turning Tool Holder ,Boring Bar, Threading Tool holder, Grooving Tool Holder , Milling Tool Holder , Milling Cutter ,Drilling Tools , Threading Insert , Grooving Insert , Turning insert , Milling insert as well as their spare parts etc.

Located in Ningbo-China, a port city with developed industries. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including DMG Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly welcome you to have a visit of our factory.

Turning Tool Holder Shipping:

| Port | Ningbo/Shanghai/Guangzhou/Hangzhou/Shenzhen/Xiamen | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory specializing in the production of external indexable turning tool holders,boring bars, threading holders and grooving holders for CNC lathes and indexable milling cutters for CNC machine center as well as their spare parts.

Q: Can we use our own logo or design?

A: Yes, we provide OEM and ODM

Q: What is your MOQ?

A: We have stock in stock for regular products, and we support a minimum order of one, and a minimum order of 20 non-standard products.

Q: How can I get some samples?

A: We are willing to provide you samples for testing after receiving the sample fee.

Q: Do you accept custom orders?

A: Of course, we are a professional manufacturer, and custom orders are what we are good at.

Ningbo SANHAN Alloy Material Co., Ltd. with years of experience in manufacture Turning Tool Holder ,Boring Bar, Threading Tool holder, Grooving Tool Holder , Milling Tool Holder , Milling Cutter ,Drilling Tools , Threading Insert , Grooving Insert , Turning insert , Milling insert as well as their spare parts etc.

Located in Ningbo-China, a port city with developed industries. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including DMG Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly welcome you to have a visit of our factory.

Turning Tool Holder Shipping:

| Port | Ningbo/Shanghai/Guangzhou/Hangzhou/Shenzhen/Xiamen | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory specializing in the production of external indexable turning tool holders,boring bars, threading holders and grooving holders for CNC lathes and indexable milling cutters for CNC machine center as well as their spare parts.

Q: Can we use our own logo or design?

A: Yes, we provide OEM and ODM

Q: What is your MOQ?

A: We have stock in stock for regular products, and we support a minimum order of one, and a minimum order of 20 non-standard products.

Q: How can I get some samples?

A: We are willing to provide you samples for testing after receiving the sample fee.

Q: Do you accept custom orders?

A: Of course, we are a professional manufacturer, and custom orders are what we are good at.

+86-19518052336

333 Liantang Road, Cidong Binhai Development Zone, Longshan Town, Cixi, Ningbo City, Zhejiang Province, China