What is Boring Bar

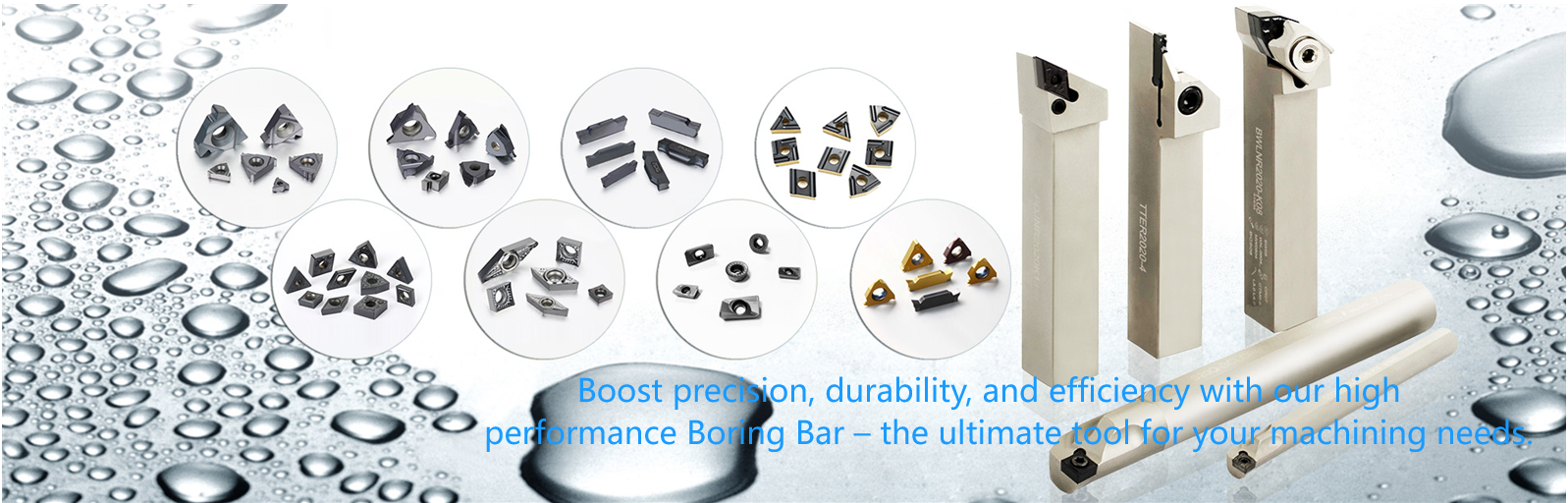

Ningbo Sanhan Alloy Materials Co., Ltd. presents its high-performance Boring Bar as an essential tool for precision machining. Designed with the latest technology and manufactured with exceptional attention to quality control, the Boring Bar is perfect for internal turning and boring applications. Known for its durability and versatility, the Boring Bar excels in reducing machining time while improving product quality, making it a preferred choice for industries such as automotive, aerospace, and general manufacturing.

The Boring Bar is engineered to meet the highest standards of precision and efficiency. With its advanced design, this tool provides smooth and accurate machining for a wide range of materials. The Boring Bar is also available with tungsten carbide inserts, offering superior hardness and wear resistance, allowing it to handle even the toughest materials. Whether you're working on CNC lathe machines or other precision machinery, this tool delivers optimal performance for internal turning operations.

Features of Boring Bar

The boring bar offers several key features that make it an indispensable tool in machining operations:

High Precision and Accuracy:

The Boring Bar ensures precise internal turning and boring, offering tight tolerances for high-quality finishes.

Durability:

Made with tungsten carbide inserts, the Boring Bar is engineered for maximum durability, ensuring long service life even under extreme working conditions.

Versatility:

Suitable for a variety of materials, including steel, aluminum, and other alloys, the Boring Bar is ideal for use in a range of industries such as automotive, aerospace, and manufacturing.

Easy Replacement of Inserts:

The Boring Bar features interchangeable tungsten carbide inserts that can be replaced quickly, ensuring minimal downtime in production.

Enhanced Cutting Performance:

The high-quality alloy steel construction and carbide inserts provide superior cutting performance, reducing the need for frequent tool changes.

Advantages of Boring Bar

Superior Cutting Performance

With its tungsten carbide inserts, the boring bar delivers exceptional cutting performance, ensuring smooth, accurate machining even on tough materials. This helps reduce machining time and enhances the quality of the final product.

Durability and Longevity

Built from high-quality tungsten carbide and alloy steel, the boring bar is engineered to withstand demanding working conditions. Its exceptional wear resistance extends tool life, reducing the frequency of tool changes and minimizing downtime in production.

High Precision

The boring bar ensures that all internal turning and boring operations are carried out with high precision, achieving tight tolerances and smooth finishes. This makes it ideal for applications in industries such as automotive, aerospace, and general manufacturing.

Versatility

The boring bar is designed to handle a wide range of materials, including steel, aluminum, and other alloys, making it a versatile tool for various machining tasks. It is suitable for both small and large scale operations.

Cost-Effective

Due to its long service life and ability to maintain high performance over time, the **Boring Bar** offers excellent value for money. The easy-to-replace inserts further contribute to its cost-effectiveness, minimizing the need for tool replacements.

Easy Maintenance

The boring bar is designed for simple maintenance, with easily replaceable inserts that can be changed with minimal effort. Regular cleaning and insert replacement help maintain optimal cutting performance, ensuring long-lasting results.

Compatibility with CNC Machines

The boring bar is designed to be compatible with a variety of CNC lathe machines, making it a convenient choice for users with different machine setups. It easily integrates into existing operations, enhancing the flexibility of your machining processes.

Customizable Solutions

For unique applications, Ningbo Sanhan Alloy Materials Co., Ltd. offers customizable **Boring Bars** to meet specific machining requirements. Whether you need different sizes, insert types, or other customizations, we can tailor the product to fit your needs.

What are the Applications of Boring Bar?

Internal Turning:

Used for turning internal surfaces of a workpiece, making it ideal for producing accurate bores.

Bore Hole Machining:

Perfect for creating bore holes of varying sizes in a range of materials.

Precision Boring:

Used for achieving high precision in boring operations, ensuring that the final product meets tight tolerance specifications.

Automotive and Aerospace:

Frequently used in the automotive and aerospace industries for producing parts that require high levels of precision, such as engine components and aircraft parts.

General Manufacturing:

Suitable for a wide variety of other applications that require internal turning and boring with tight tolerances.

FAQs About Boring Bar

Q1: What is a boring bar used for?

Q2: What materials can the boring bar be used on?

Q3: How long does the boring bar last?

Q4: Can I replace the inserts myself?

Q5: How do I maintain my boring bar?

Latest Blogs in Boring Bar Industry

-

Carbide tool holders are an essential component of metal cutting applications, providing stability, precision, and durability. These tool holders are designed to securely hold the cutting tools in place, ensuring accurate and efficient machining operations. In this article, we will explore the diffe

Carbide tool holders are an essential component of metal cutting applications, providing stability, precision, and durability. These tool holders are designed to securely hold the cutting tools in place, ensuring accurate and efficient machining operations. In this article, we will explore the diffe -

Manufacturers of medical devices often rely on the precision of carbide tool holders to produce high-quality parts. These tool holders are essential in the medical device industry, where precision and quality are paramount. In this article, we will explore the various types of carbide tool holders a

Manufacturers of medical devices often rely on the precision of carbide tool holders to produce high-quality parts. These tool holders are essential in the medical device industry, where precision and quality are paramount. In this article, we will explore the various types of carbide tool holders a

English

English