Product Model

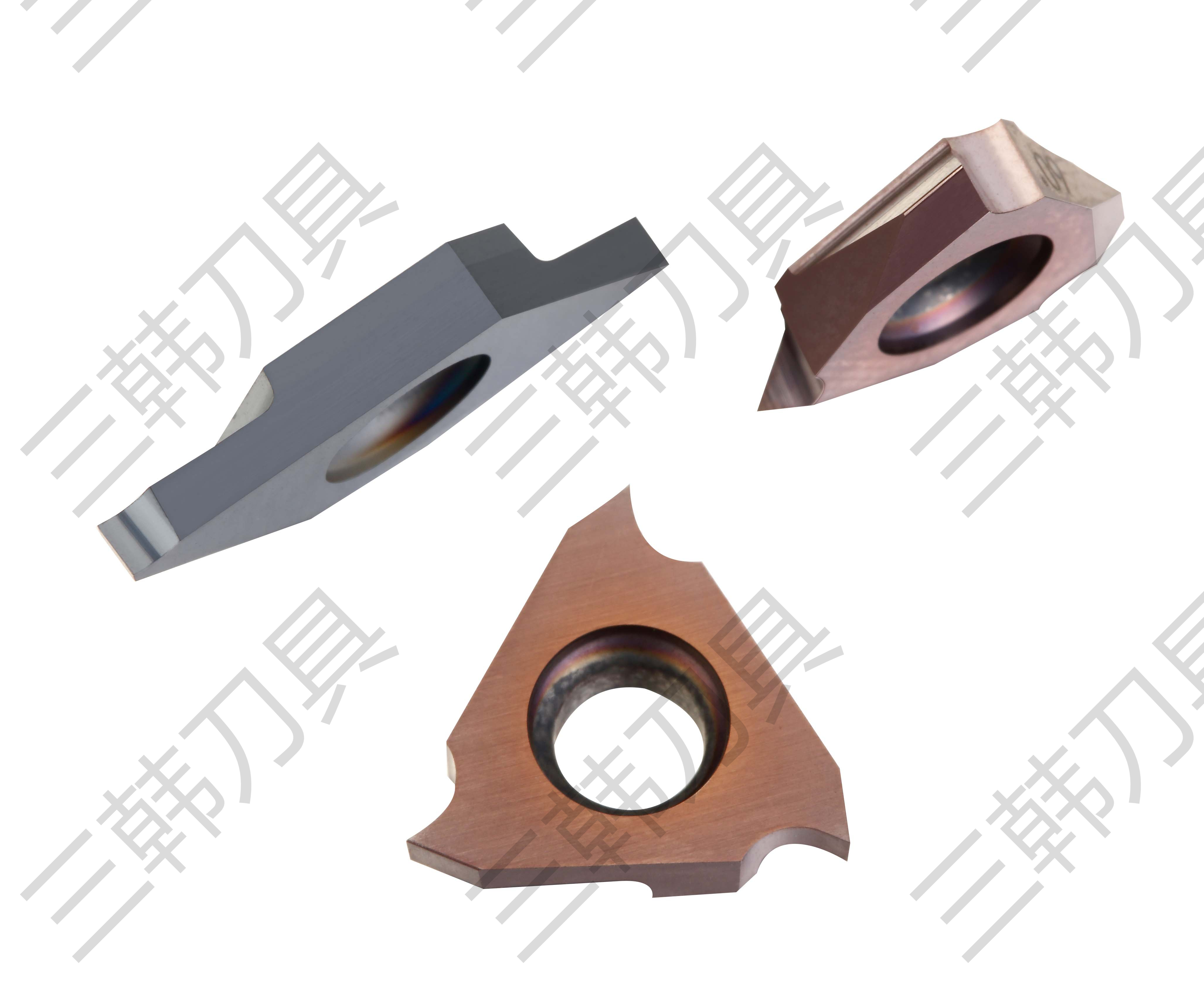

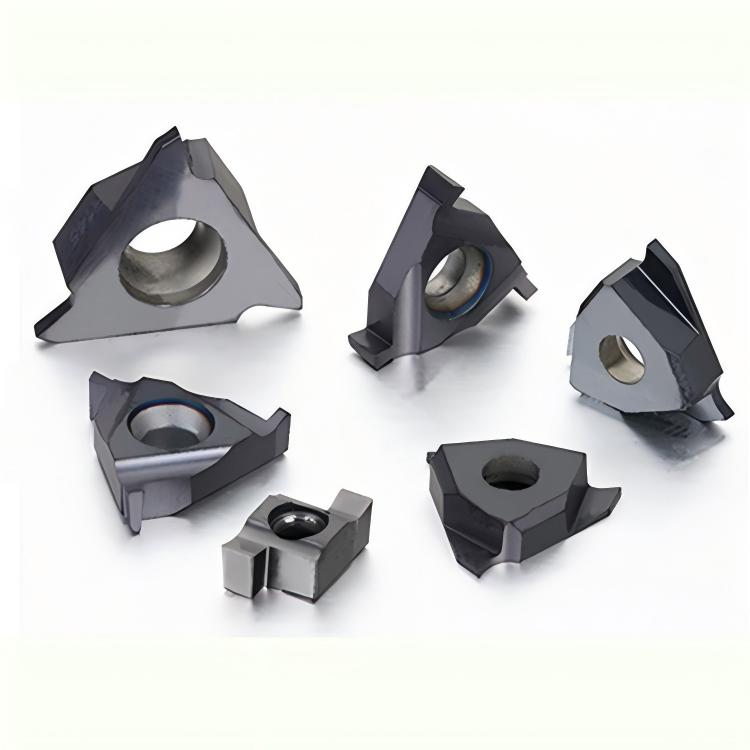

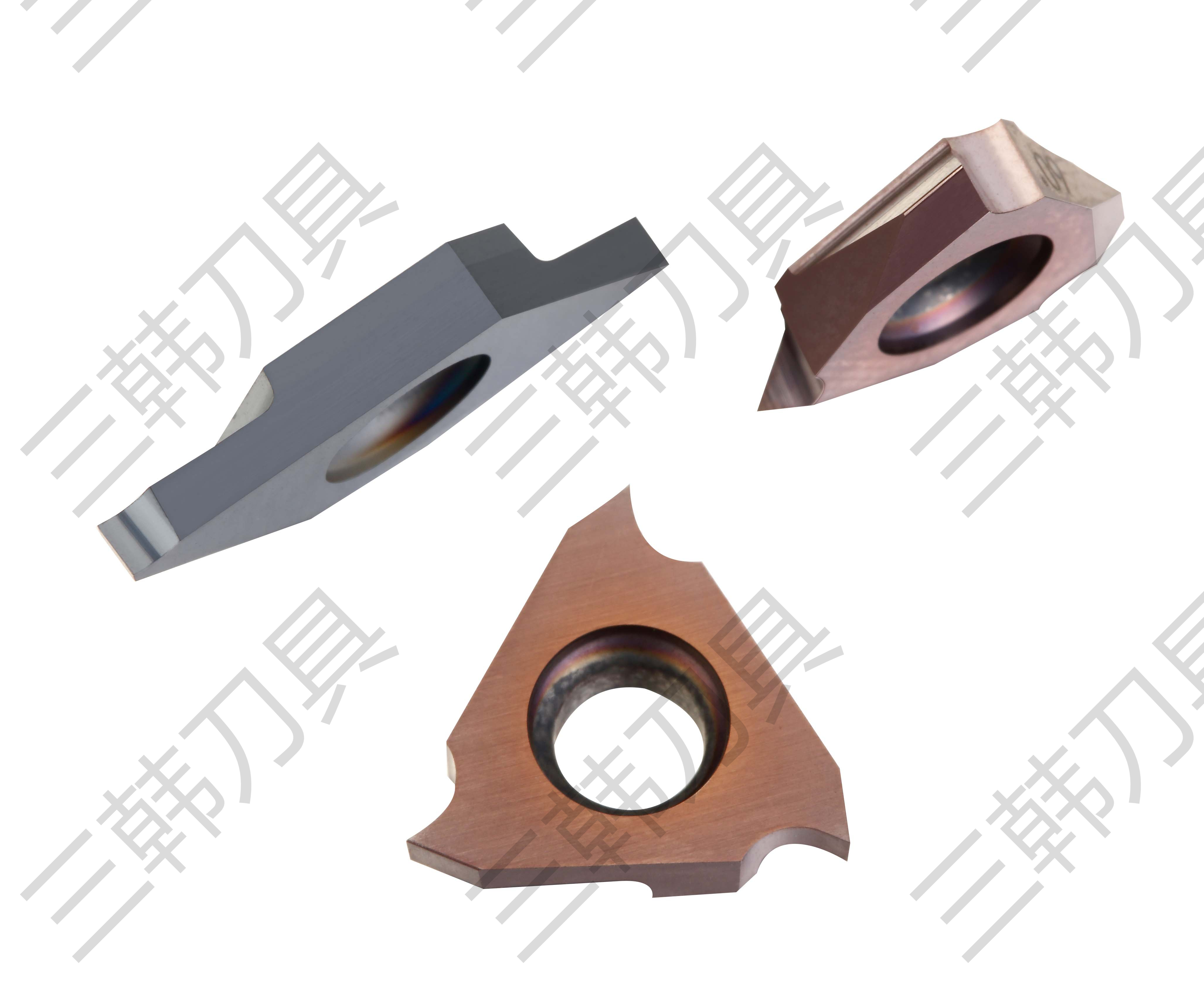

Sandhog Threading Inserts: Fully Ground & Pressed Options with Metric, American, British Standards,

Over 1,000,000 in Stock, Ensuring Superior Chip Removal & Machining Accuracy

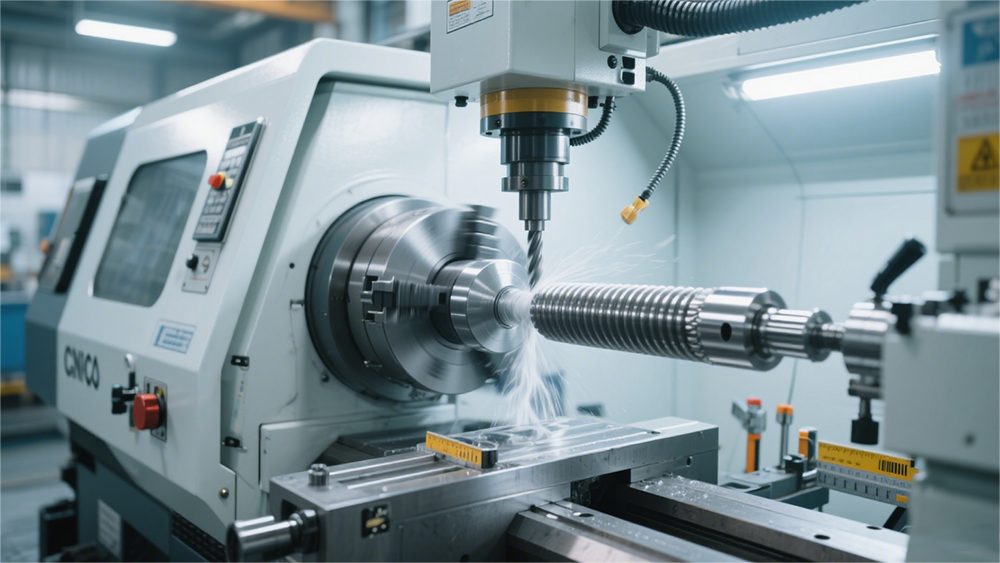

Application

Metal Processing Machinery Parts

Suitable for manufacturing metal processing machinery parts, ensuring high - precision thread processing and enhancing the quality and performance of parts.

Automotive Industry

Applied in the automotive industry for machining various components with threaded parts, like engine parts and transmission components, meeting the industry's high - standard requirements for thread accuracy and durability.

Aerospace and Medical Industries

Used in aerospace and medical industries to process parts with strict precision and quality demands. In aerospace, it can be used for manufacturing engine and structural parts; in the medical field, it can be used for producing surgical instruments and implant components.

Multiple Metal Materials Machining

Capable of machining a wide range of metal materials such as steel, alloy steel, and stainless steel, adapting to different processing requirements in various industrial applications.

Product Advantages

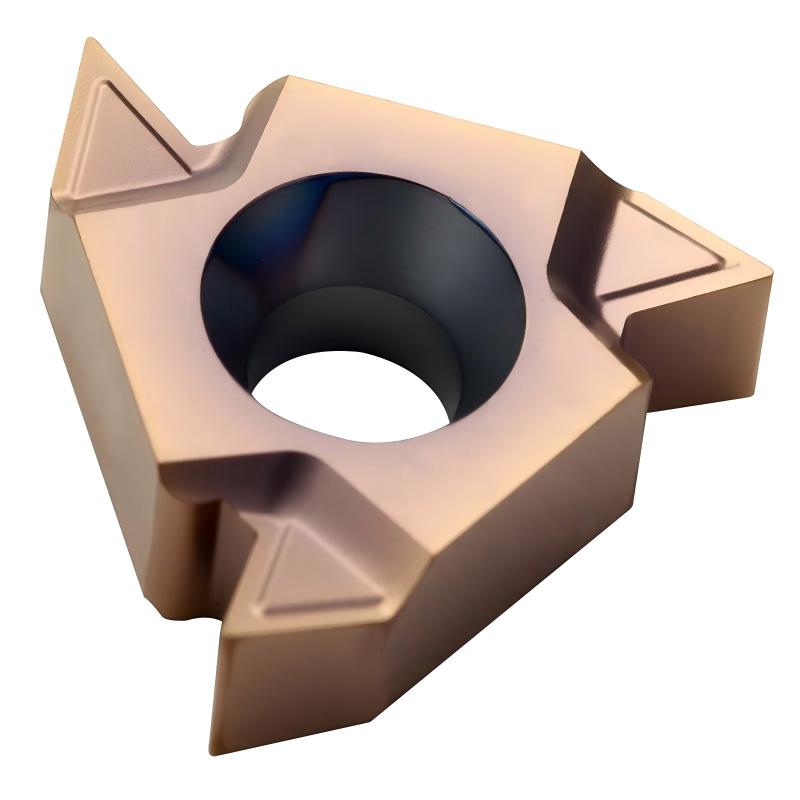

High Durability

Made of tungsten carbide, it has excellent hardness and wear - resistance. It can withstand high - temperature and heavy - load processing without losing its sharpness, with a long service life, which can save the cost and time of frequent replacement.

High - precision Processing

The sharp cutting edge can perform high - speed processing with minimal vibration, achieving a smoother surface finish and stricter tolerances, which is especially suitable for applications requiring high precision, such as the automotive and aerospace industries.

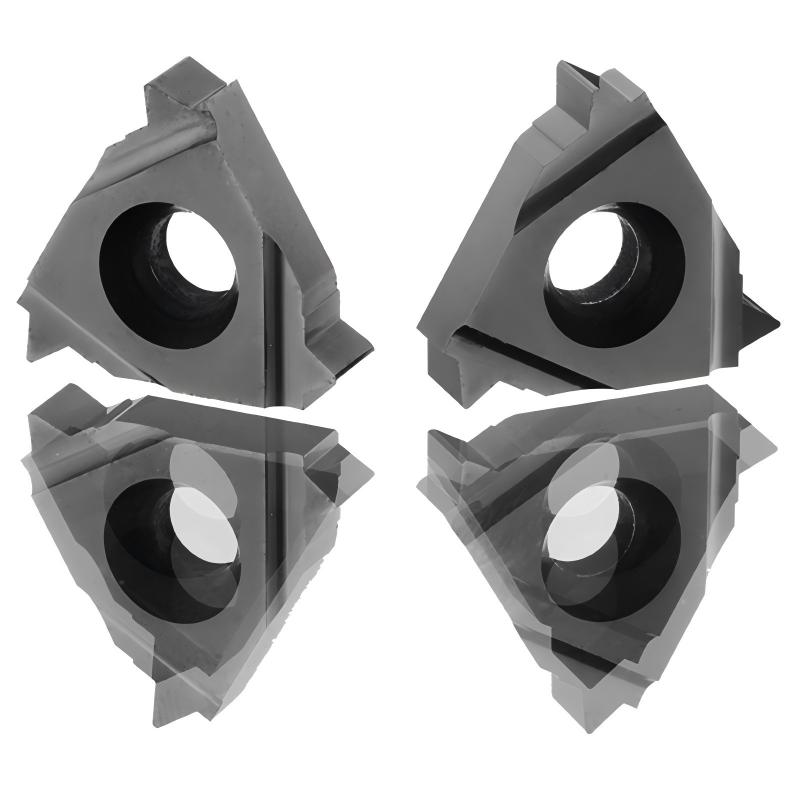

Strong Versatility

It can be used for a variety of materials, including steel, stainless steel, cast iron and non - ferrous metals, and is suitable for various processing operations from roughing to finishing, which can meet the processing needs of different industries.

FAQs

Q: What materials can this 16ER/IR series threading insert be used to machine?

A: Highly versatile, suitable for steel, alloy steel, stainless steel, cast iron and some non-ferrous metals, fitting automotive, aerospace and manufacturing.

Q: Do you provide samples of the 16ER/IR threading inserts?

A: Yes. Contact customer service for free samples to test performance and quality before bulk orders.

Q: Are you a manufacturer? And do you support custom orders for the 16ER/IR threading inserts?

A: We are a certified factory. Custom orders are accepted for dimensions, coatings, etc. Contact us with specific needs.

Related Blogs

-

Threaded tool holders have emerged as a versatile solution for a wide range of materials in various industries. These holders offer numerous benefits, making them an indispensable tool for professionals. With their ability to securely hold various cutting tools, threaded tool holders ensure precisio

Threaded tool holders have emerged as a versatile solution for a wide range of materials in various industries. These holders offer numerous benefits, making them an indispensable tool for professionals. With their ability to securely hold various cutting tools, threaded tool holders ensure precisio -

In the automotive industry, precision and reliability are paramount when it comes to manufacturing parts. One crucial aspect that directly impacts these factors is the tooling used in the production process. The introduction of threaded tool holders has revolutionized the way automotive parts are ma

In the automotive industry, precision and reliability are paramount when it comes to manufacturing parts. One crucial aspect that directly impacts these factors is the tooling used in the production process. The introduction of threaded tool holders has revolutionized the way automotive parts are ma -

In the world of mold processing, accuracy is paramount. The ability to create intricate and precise molds can make all the difference in the final product. That's where a threaded tool holder comes into play. This innovative tool holder is designed to improve mold processing accuracy, revolutionizin

In the world of mold processing, accuracy is paramount. The ability to create intricate and precise molds can make all the difference in the final product. That's where a threaded tool holder comes into play. This innovative tool holder is designed to improve mold processing accuracy, revolutionizin

Keep in touch with us

Phone/WhatsApp/Skype

+86-13185986149

Address:

333 Liantang Road, Cidong Binhai Development Zone, Longshan Town, Cixi, Ningbo City, Zhejiang Province, China

English

English