English

EnglishCALL US

+86-19518052336

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

EnglishS16Q-SDQCR11

Sandhog

Revolutionary Locked Tool Design: Unlike conventional cartridge-style bars, the S16Q-SDQCR11 features a solid, integrated shank and head. The cutting insert is securely clamped directly into the monolithic body. This design maximizes rigidity by over 300% compared to modular systems, dramatically reducing chatter and allowing for heavier, more productive cuts.

Unmatched Stability for Deep Reaching: The S16Q shank designation indicates an extra-rigid, short-back design optimized for stability. When combined with the SDQCR11 locked head, it provides exceptional reach-to-diameter ratios, enabling you to bore deeper with confidence and maintain critical tolerances.

Precision-Ground Geometry: The integral pocket and seating surfaces are precision-ground to micron-level tolerances. This guarantees perfect insert placement every time, ensuring repeatable accuracy, consistent tool life, and superior surface finishes straight out of the holder.

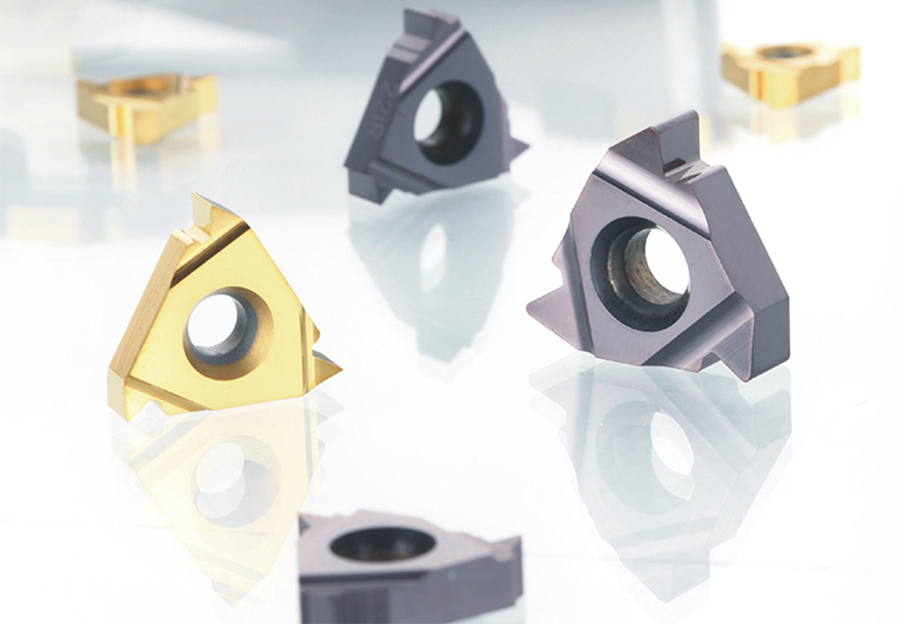

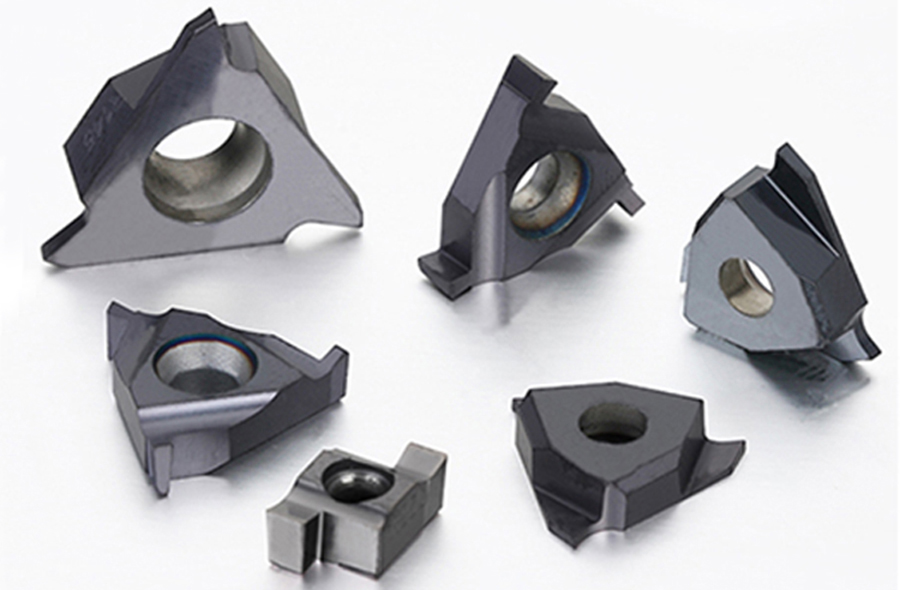

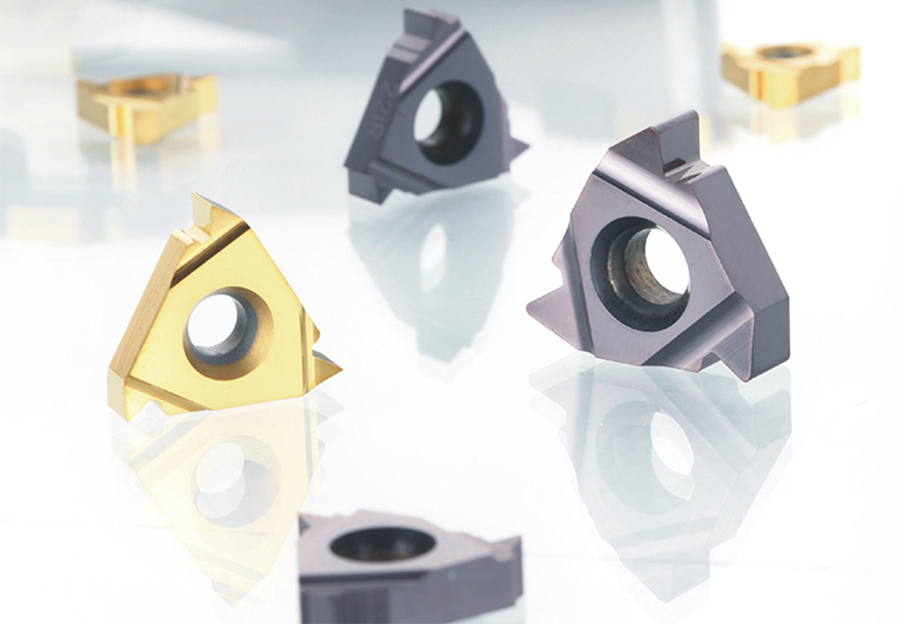

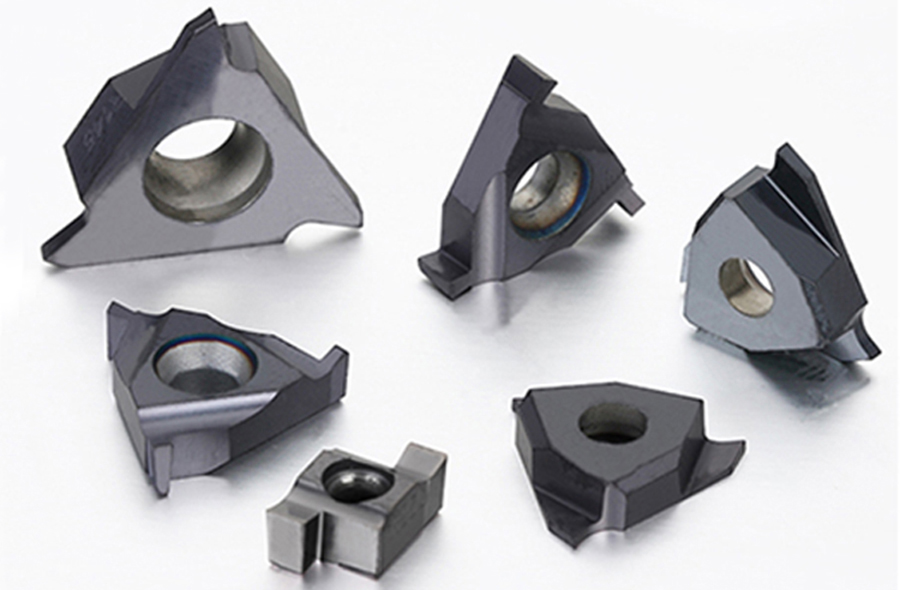

Optimized for Sandhog SDQCR11 Inserts: Designed specifically for the SDQCR11 insert style (a high-positive, 80° diamond/cosine geometry with a 11/32" IC). This versatile insert geometry offers multiple cutting edges, excellent chip control, and free-cutting action for both roughing and finishing operations.

Enhanced Coolant Delivery: Features dedicated coolant channels engineered to deliver high-pressure coolant directly to the cutting edge. This effectively breaks chips, reduces heat, and prolongs tool life, especially in stringy materials.

Heavy-Duty Construction: Manufactured from premium, heat-treated alloy steel, providing the ultimate strength and fatigue resistance for continuous production environments.

Technical Specifications

Model: S16Q-SDQCR11 (Complete Boring Bar Assembly)

Tool Type: Locked (Solid) Internal Boring Bar

Shank Style: S16Q (Short, Rigid Profile)

Cutting Head: Integral, Locked SDQCR11

Insert Compatibility: Sandhog SDQCR-XXXX (e.g., SDQCR11-M, specific grade/subgeometry)

Insert Geometry: 80° Diamond (Cosine)

Inscribed Circle (IC): 11/32"

Recommended Bore Diameter Range: (Consult Dimensional Drawings for Minimum Bore & Reach)

Primary Application: Precision internal boring, finishing, and semi-roughing on CNC machining centers and turning centers.

| SDQCR/L | |||||||||||

| Designation | size / Размер | Inserts | Screw | Wrench | |||||||

| Тип | dmin | φd | S | L | ℓ | H | f | α° | Пластины | винт | Ключ |

| S08K-SDQCR/L07 | 12 | 8 | 6 | 125 | 22 | 7 | 2 | 12° | DC**0702** | M2.5X5 | T-8 |

| S10K-SDQCR/L07 | 13 | 10 | 7 | 125 | 24 | 9 | 2 | 10° | M2.5X6 | ||

| S12M-SDQCR/L07 | 16 | 12 | 9 | 150 | 30 | 11 | 3 | 8° | |||

| S16Q-SDQCR/L07 | 20 | 16 | 11 | 180 | 30 | 15 | 3 | 6° | |||

| S20Q-SDQCR/L07 | 25 | 20 | 13 | 180 | 42 | 18 | 3 | 6° | |||

| S16Q-SDQCR/L11 | 20 | 16 | 11 | 180 | 32 | 15 | 3 | 8° | DC**11T3** | M3.5X9 | T-15 |

| S20Q-SDQCR/L11 | 25 | 20 | 13 | 180 | 42 | 18 | 3 | 6° | |||

| S25R-SDQCR/L11 | 32 | 25 | 17 | 200 | 43 | 23 | 4 | 5° | |||

| S32S-SDQCR/L11 | 40 | 32 | 22 | 250 | 45 | 30 | 6 | 4° | |||

Company Information :

Ningbo SANHAN Alloy Material Co., Ltd. with years of experience in manufacture Turning Tool Holder ,Boring Bar ,Threading Tool holder , Grooving Tool Holder , Milling Tool Holder , Milling Cutter ,Drilling Tools , Threading Insert ,Grooving Insert , Turning insert , Milling insert as well as their spare parts etc.

Located in Ningbo-China, a port city with developed industries. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including DMG Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly Welcome you to have a visit of our factory .

Turning Tool Holder Shipping:

| Port | Ningbo/Shanghai/Guangzhou/Hangzhou/Shenzhen/Xiamen | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory specializing in the production of external indexable turning tool holders,boring bars, threading holders and grooving holders for CNC lathes and indexable milling cutters for CNC machine center as well as their spare parts.

Q: Can we use our own logo or design?

A: Yes, we provide OEM and ODM

Q: What is your MOQ?

A: We have stock in stock for regular products, and we support a minimum order of one, and a minimum order of 20 non-standard products.

Q: How can I get some samples?

A: We are willing to provide you samples for testing after receiving the sample fee.

Q: Do you accept custom orders?

A: Of course, we are a professional manufacturer, and custom orders are what we are good at.

Revolutionary Locked Tool Design: Unlike conventional cartridge-style bars, the S16Q-SDQCR11 features a solid, integrated shank and head. The cutting insert is securely clamped directly into the monolithic body. This design maximizes rigidity by over 300% compared to modular systems, dramatically reducing chatter and allowing for heavier, more productive cuts.

Unmatched Stability for Deep Reaching: The S16Q shank designation indicates an extra-rigid, short-back design optimized for stability. When combined with the SDQCR11 locked head, it provides exceptional reach-to-diameter ratios, enabling you to bore deeper with confidence and maintain critical tolerances.

Precision-Ground Geometry: The integral pocket and seating surfaces are precision-ground to micron-level tolerances. This guarantees perfect insert placement every time, ensuring repeatable accuracy, consistent tool life, and superior surface finishes straight out of the holder.

Optimized for Sandhog SDQCR11 Inserts: Designed specifically for the SDQCR11 insert style (a high-positive, 80° diamond/cosine geometry with a 11/32" IC). This versatile insert geometry offers multiple cutting edges, excellent chip control, and free-cutting action for both roughing and finishing operations.

Enhanced Coolant Delivery: Features dedicated coolant channels engineered to deliver high-pressure coolant directly to the cutting edge. This effectively breaks chips, reduces heat, and prolongs tool life, especially in stringy materials.

Heavy-Duty Construction: Manufactured from premium, heat-treated alloy steel, providing the ultimate strength and fatigue resistance for continuous production environments.

Technical Specifications

Model: S16Q-SDQCR11 (Complete Boring Bar Assembly)

Tool Type: Locked (Solid) Internal Boring Bar

Shank Style: S16Q (Short, Rigid Profile)

Cutting Head: Integral, Locked SDQCR11

Insert Compatibility: Sandhog SDQCR-XXXX (e.g., SDQCR11-M, specific grade/subgeometry)

Insert Geometry: 80° Diamond (Cosine)

Inscribed Circle (IC): 11/32"

Recommended Bore Diameter Range: (Consult Dimensional Drawings for Minimum Bore & Reach)

Primary Application: Precision internal boring, finishing, and semi-roughing on CNC machining centers and turning centers.

| SDQCR/L | |||||||||||

| Designation | size / Размер | Inserts | Screw | Wrench | |||||||

| Тип | dmin | φd | S | L | ℓ | H | f | α° | Пластины | винт | Ключ |

| S08K-SDQCR/L07 | 12 | 8 | 6 | 125 | 22 | 7 | 2 | 12° | DC**0702** | M2.5X5 | T-8 |

| S10K-SDQCR/L07 | 13 | 10 | 7 | 125 | 24 | 9 | 2 | 10° | M2.5X6 | ||

| S12M-SDQCR/L07 | 16 | 12 | 9 | 150 | 30 | 11 | 3 | 8° | |||

| S16Q-SDQCR/L07 | 20 | 16 | 11 | 180 | 30 | 15 | 3 | 6° | |||

| S20Q-SDQCR/L07 | 25 | 20 | 13 | 180 | 42 | 18 | 3 | 6° | |||

| S16Q-SDQCR/L11 | 20 | 16 | 11 | 180 | 32 | 15 | 3 | 8° | DC**11T3** | M3.5X9 | T-15 |

| S20Q-SDQCR/L11 | 25 | 20 | 13 | 180 | 42 | 18 | 3 | 6° | |||

| S25R-SDQCR/L11 | 32 | 25 | 17 | 200 | 43 | 23 | 4 | 5° | |||

| S32S-SDQCR/L11 | 40 | 32 | 22 | 250 | 45 | 30 | 6 | 4° | |||

Company Information :

Ningbo SANHAN Alloy Material Co., Ltd. with years of experience in manufacture Turning Tool Holder ,Boring Bar ,Threading Tool holder , Grooving Tool Holder , Milling Tool Holder , Milling Cutter ,Drilling Tools , Threading Insert ,Grooving Insert , Turning insert , Milling insert as well as their spare parts etc.

Located in Ningbo-China, a port city with developed industries. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including DMG Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly Welcome you to have a visit of our factory .

Turning Tool Holder Shipping:

| Port | Ningbo/Shanghai/Guangzhou/Hangzhou/Shenzhen/Xiamen | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory specializing in the production of external indexable turning tool holders,boring bars, threading holders and grooving holders for CNC lathes and indexable milling cutters for CNC machine center as well as their spare parts.

Q: Can we use our own logo or design?

A: Yes, we provide OEM and ODM

Q: What is your MOQ?

A: We have stock in stock for regular products, and we support a minimum order of one, and a minimum order of 20 non-standard products.

Q: How can I get some samples?

A: We are willing to provide you samples for testing after receiving the sample fee.

Q: Do you accept custom orders?

A: Of course, we are a professional manufacturer, and custom orders are what we are good at.

+86-19518052336

333 Liantang Road, Cidong Binhai Development Zone, Longshan Town, Cixi, Ningbo City, Zhejiang Province, China