English

EnglishCALL US

+86-19518052336

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

SCLCR2020K09

SANDHOG

The Sandhog Precision SCLCR2020K09 turning tool holder is engineered for machinists who refuse to compromise on accuracy, rigidity, and tool life. Designed for external turning, facing, and profiling operations, this clamping-style (SCLCR) holder delivers exceptional stability, making it the ideal choice for high-precision CNC turning in metals, alloys, and advanced engineering materials.

Key Features & Benefits

Unmatched Rigidity & Stability:

Forged & Hardened Body: Manufactured from premium alloy steel and precision heat-treated, the holder body provides maximum resistance to deflection and vibration under heavy cuts.

Secure Clamping Mechanism: The robust lever-clamp design ensures a powerful, consistent, and reliable grip on the cutting insert, eliminating insert movement for superior surface finishes and tight tolerance holding.

Superior Precision & Repeatability:

Ground Seating Surfaces: Critical contact surfaces are precision-ground to guarantee perfect insert positioning every time. This minimizes runout and ensures consistent tool geometry, part after part.

Optimized for Fine Finishing: The design minimizes overhang and maximizes in-cut stability, enabling exceptional surface finishes and the ability to hold tight geometric tolerances.

Maximum Productivity & Cost Efficiency:

Excellent Chip Evacuation: The open-face design and optimized groove geometry allow for unrestricted chip flow, preventing chip jamming and protecting the workpiece and insert.

Extended Tool Life: By reducing vibration and ensuring perfect insert seating, the holder minimizes notching and premature wear on the cutting edge, lowering your cost per part.

Standardized Compatibility & Ease of Use:

SCLCR: Clamping Style, Left-Hand Cut, Right-Hand Tool (for conventional turning towards the chuck).

20: 20mm square shank size.

20: Tool height (approx. 20mm).

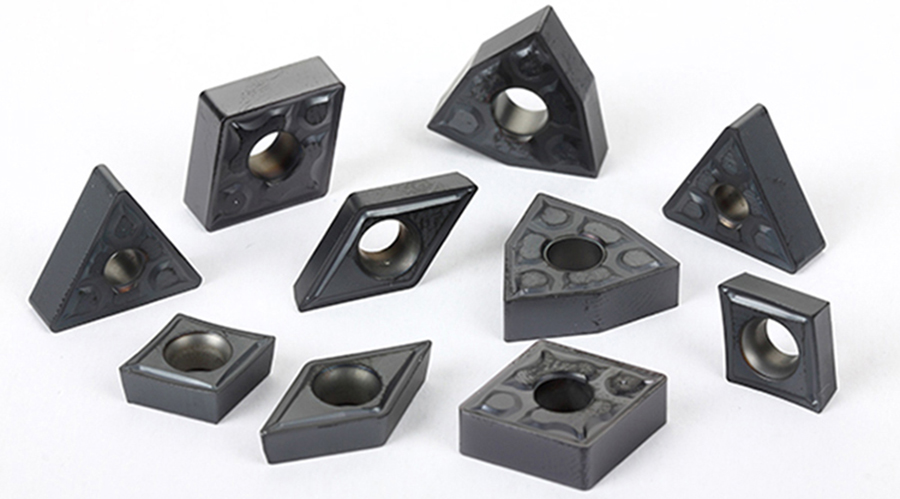

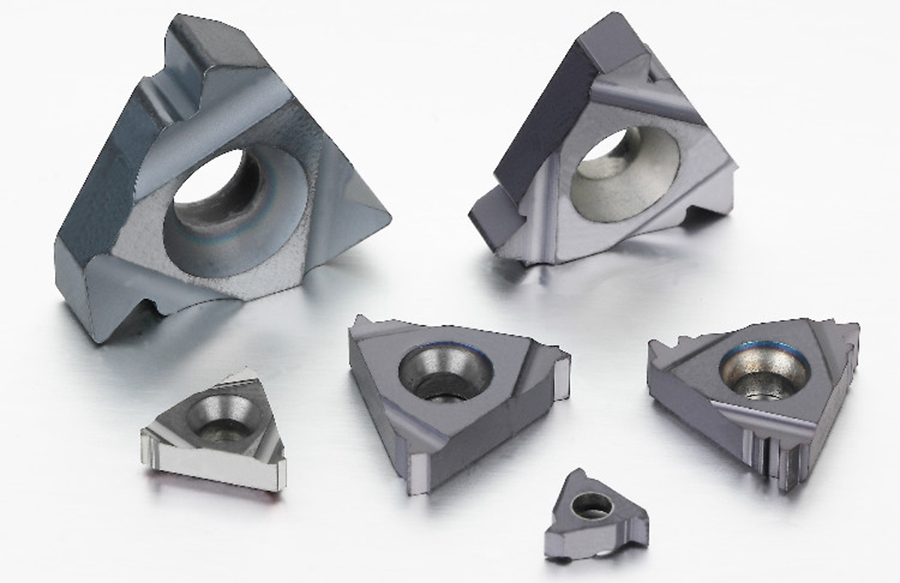

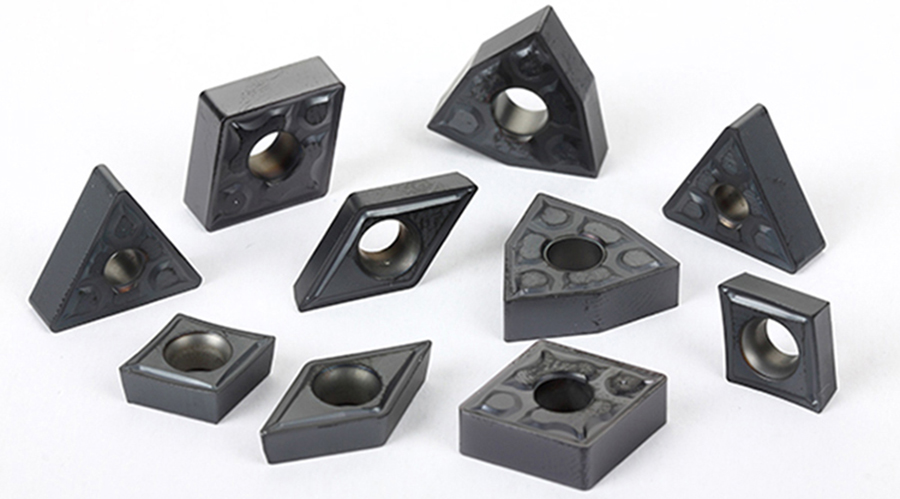

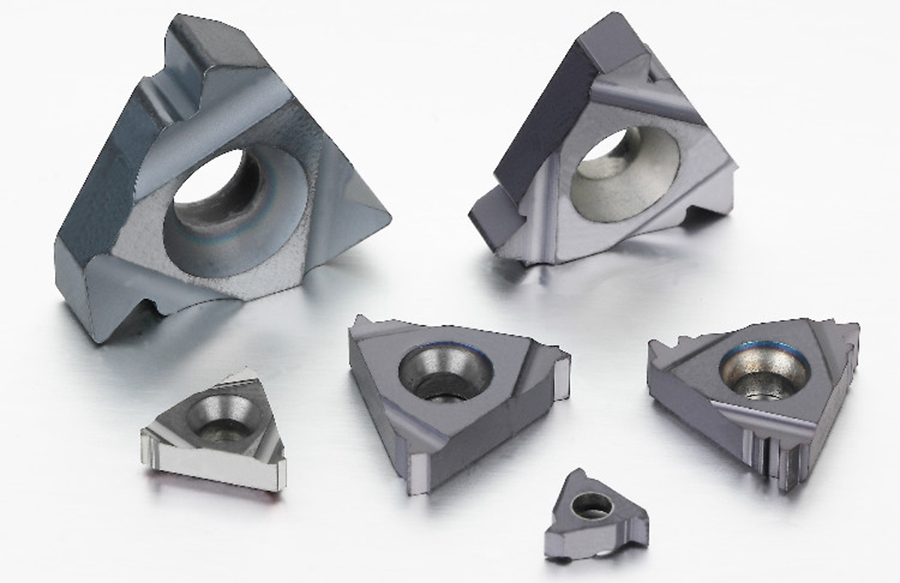

K09: Specific insert clamping geometry for K-type (diamond-shaped) inserts with a 9mm inscribed circle.

Standard Tooling Interface: Conforms to the industry-standard SCLCR 2020K-09 designation.

Quick & Easy Insert Changes: The user-friendly clamp lever allows for fast, tool-less insert indexing and replacement, minimizing machine downtime.

Company Information :

Ningbo SANHAN Alloy Material Co., Ltd. with years of experience in manufacture Turning Tool Holder ,Boring Bar ,Threading Tool holder , Grooving Tool Holder , Milling Tool Holder , Milling Cutter ,Drilling Tools , Threading Insert , Grooving Insert , Turning insert , Milling insert as well as their spare parts etc.

Located in Ningbo-China, a port city with developed industries. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including DMG Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly Welcome you to have a visit of our factory .

Turning Tool Holder Shipping:

| Port | Ningbo/Shanghai/Guangzhou/Hangzhou/Shenzhen/Xiamen | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory specializing in the production of external indexable turning tool holders,boring bars, threading

holders and grooving holders for CNC lathes and indexable milling cutters for CNC machine center as well as their

spare parts.

Q: Can we use our own logo or design?

A: Yes, we provide OEM and ODM

Q: What is your MOQ?

A: We have stock in stock for regular products, and we support a minimum order of one, and a minimum order of 20 non-standard products.

Q: How can I get some samples?

A: We are willing to provide you samples for testing after receiving the sample fee.

Q: Do you accept custom orders?

A: Of course, we are a professional manufacturer, and custom orders are what we are good at.

The Sandhog Precision SCLCR2020K09 turning tool holder is engineered for machinists who refuse to compromise on accuracy, rigidity, and tool life. Designed for external turning, facing, and profiling operations, this clamping-style (SCLCR) holder delivers exceptional stability, making it the ideal choice for high-precision CNC turning in metals, alloys, and advanced engineering materials.

Key Features & Benefits

Unmatched Rigidity & Stability:

Forged & Hardened Body: Manufactured from premium alloy steel and precision heat-treated, the holder body provides maximum resistance to deflection and vibration under heavy cuts.

Secure Clamping Mechanism: The robust lever-clamp design ensures a powerful, consistent, and reliable grip on the cutting insert, eliminating insert movement for superior surface finishes and tight tolerance holding.

Superior Precision & Repeatability:

Ground Seating Surfaces: Critical contact surfaces are precision-ground to guarantee perfect insert positioning every time. This minimizes runout and ensures consistent tool geometry, part after part.

Optimized for Fine Finishing: The design minimizes overhang and maximizes in-cut stability, enabling exceptional surface finishes and the ability to hold tight geometric tolerances.

Maximum Productivity & Cost Efficiency:

Excellent Chip Evacuation: The open-face design and optimized groove geometry allow for unrestricted chip flow, preventing chip jamming and protecting the workpiece and insert.

Extended Tool Life: By reducing vibration and ensuring perfect insert seating, the holder minimizes notching and premature wear on the cutting edge, lowering your cost per part.

Standardized Compatibility & Ease of Use:

SCLCR: Clamping Style, Left-Hand Cut, Right-Hand Tool (for conventional turning towards the chuck).

20: 20mm square shank size.

20: Tool height (approx. 20mm).

K09: Specific insert clamping geometry for K-type (diamond-shaped) inserts with a 9mm inscribed circle.

Standard Tooling Interface: Conforms to the industry-standard SCLCR 2020K-09 designation.

Quick & Easy Insert Changes: The user-friendly clamp lever allows for fast, tool-less insert indexing and replacement, minimizing machine downtime.

Company Information :

Ningbo SANHAN Alloy Material Co., Ltd. with years of experience in manufacture Turning Tool Holder ,Boring Bar ,Threading Tool holder , Grooving Tool Holder , Milling Tool Holder , Milling Cutter ,Drilling Tools , Threading Insert , Grooving Insert , Turning insert , Milling insert as well as their spare parts etc.

Located in Ningbo-China, a port city with developed industries. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including DMG Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly Welcome you to have a visit of our factory .

Turning Tool Holder Shipping:

| Port | Ningbo/Shanghai/Guangzhou/Hangzhou/Shenzhen/Xiamen | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory specializing in the production of external indexable turning tool holders,boring bars, threading

holders and grooving holders for CNC lathes and indexable milling cutters for CNC machine center as well as their

spare parts.

Q: Can we use our own logo or design?

A: Yes, we provide OEM and ODM

Q: What is your MOQ?

A: We have stock in stock for regular products, and we support a minimum order of one, and a minimum order of 20 non-standard products.

Q: How can I get some samples?

A: We are willing to provide you samples for testing after receiving the sample fee.

Q: Do you accept custom orders?

A: Of course, we are a professional manufacturer, and custom orders are what we are good at.

+86-19518052336

333 Liantang Road, Cidong Binhai Development Zone, Longshan Town, Cixi, Ningbo City, Zhejiang Province, China