English

EnglishCALL US

+86-19518052336

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English| Availability: | |

|---|---|

| Quantity: | |

SCKCR2020K09

SANDHOG

Unmatched Rigidity & Damping: Manufactured from premium micro-grain solid tungsten carbide, the SCKCR2020K09 provides approximately 3x the stiffness of an equivalent steel shank. This dramatically reduces vibration, chatter, and tool deflection, enabling stable machining at higher depths of cut and longer overhangs.

Exceptional Surface Finish: The inherent stability of the solid carbide construction minimizes harmonic vibration, allowing you to produce superior internal surface finishes and hold tighter tolerances consistently, often eliminating secondary finishing operations.

Optimized for Deep Reach: The 20mm diameter (D1) and 200mm length (L1) make this bar an ideal choice for deep cavity work. The SCKCR (Clamp) style head provides excellent insert seating and clearance. Its strength allows for productive machining where steel bars would fail.

Precision Ground Shank & Geometry: Featuring a ground 20mm round shank with a precise 9mm hole depth (H) for the locking screw, this bar guarantees perfect concentricity and reliable, repeatable clamping in your CNC tool holder, essential for high-accuracy work.

Durable & Wear-Resistant: Tungsten carbide offers excellent resistance to abrasion and heat, ensuring longer tool life and more consistent performance over time compared to high-speed steel (HSS) or heavy-metal bars.

Technical Specifications:

Tool Type: Solid Tungsten Carbide Boring Bar

ISO Designation: SCKCR2020K09

Boring Style: SCKCR (90° Lead Angle, Clamp-type Top Lock)

Shank Diameter (D1): 20 mm

Total Length (L1): 200 mm

Cutting Depth: Dependent on insert size (See compatible inserts below)

Hole Depth (H): 9 mm

Coolant Through: Optional (depending on specific supplier variant)

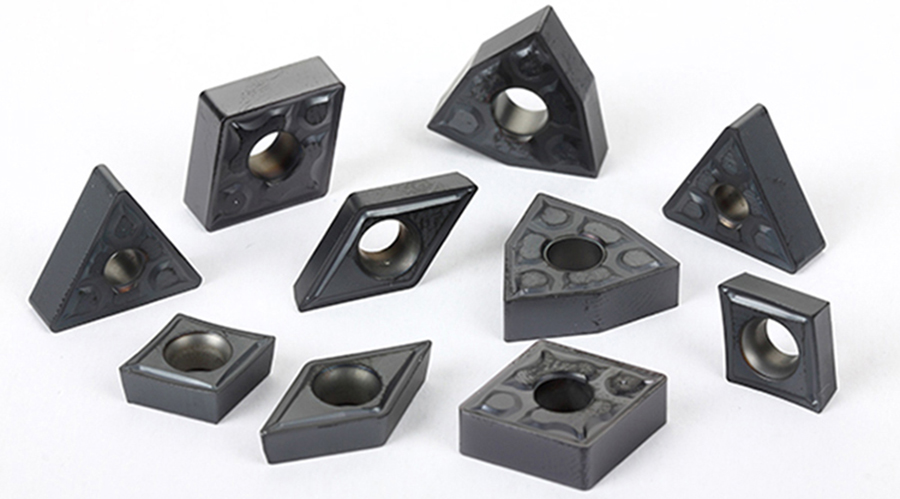

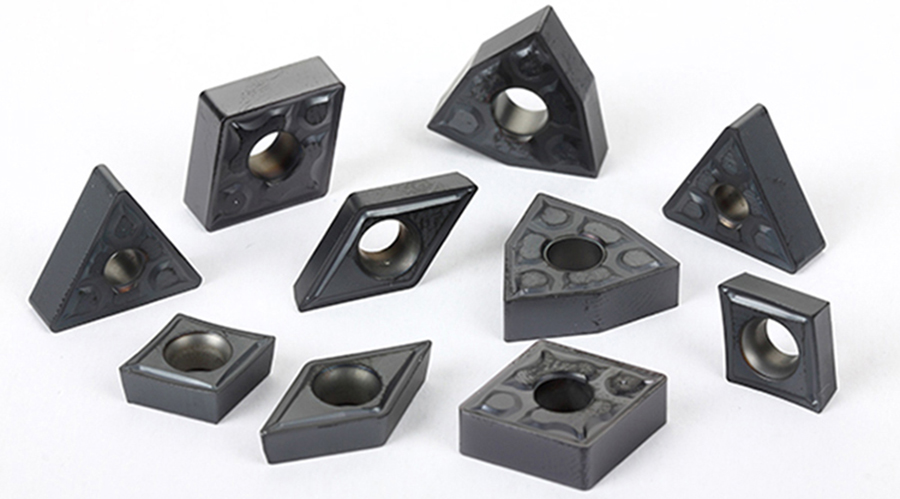

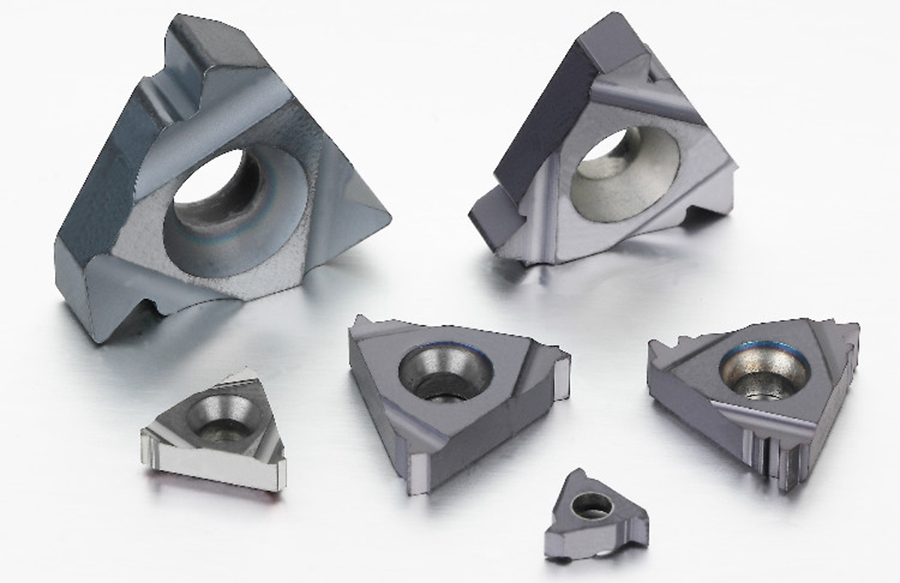

Compatible Insert Recommendation:

Deep hole boring and internal turning

Machining high-tensile materials (e.g., stainless steels, Inconel, titanium, hardened steels)

High-precision bore finishing

Internal grooving and profiling

Operations where chatter and poor finish are problematic

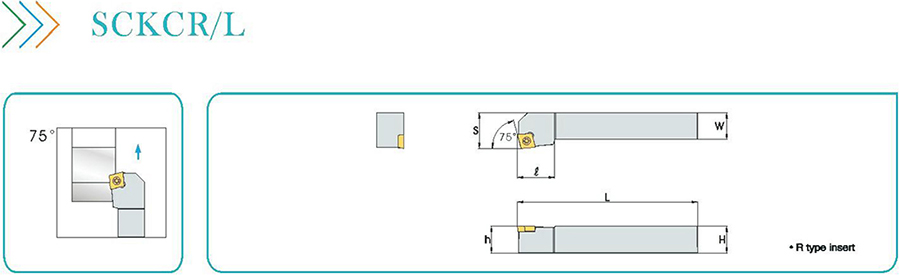

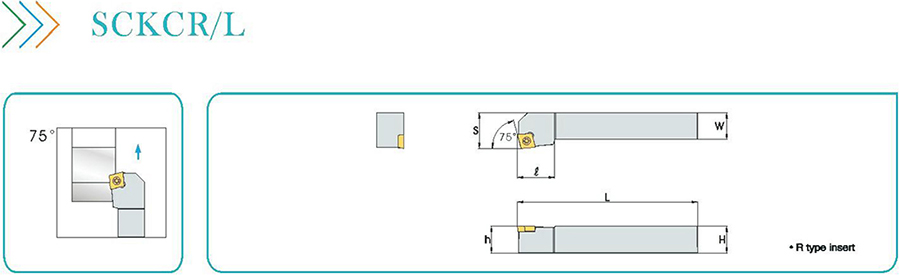

| ▷SCKCR/L | |||||||||

| Designation | size / Размер | Inserts | Screw | Wrench | |||||

| H | W | L | ℓ | h | s | ||||

| Тип | Пластины | винт | Ключ | ||||||

| SCKCR/L2020K09 | 20 | 20 | 125 | 23 | 20 | 25 | CC**09T3** | M3.5X9 | T15 |

| SCKCR/L2525M09 | 25 | 25 | 150 | 23 | 25 | 32 | |||

| SCKCR/L2020K12 | 20 | 20 | 125 | 28 | 20 | 25 | CC**1204** | M5X12 | T20 |

| SCKCR/L2525M12 | 25 | 25 | 150 | 28 | 25 | 32 | |||

Company Information :

Ningbo SANHAN Alloy Material Co., Ltd. with years of experience in manufacture Turning Tool Holder ,Boring Bar ,Threading Tool holder , Grooving Tool Holder , Milling Tool Holder , Milling Cutter ,Drilling Tools , Threading Insert , Grooving Insert , Turning insert , Milling insert as well as their spare parts etc.

Located in Ningbo-China, a port city with developed industries. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including DMG Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly Welcome you to have a visit of our factory .

Turning Tool Holder Shipping:

| Port | Ningbo/Shanghai/Guangzhou/Hangzhou/Shenzhen/Xiamen | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory specializing in the production of external indexable turning tool holders,boring bars, threading

holders and grooving holders for CNC lathes and indexable milling cutters for CNC machine center as well as their

spare parts.

Q: Can we use our own logo or design?

A: Yes, we provide OEM and ODM

Q: What is your MOQ?

A: We have stock in stock for regular products, and we support a minimum order of one, and a minimum order of 20 non-standard products.

Q: How can I get some samples?

A: We are willing to provide you samples for testing after receiving the sample fee.

Q: Do you accept custom orders?

A: Of course, we are a professional manufacturer, and custom orders are what we are good at.

Unmatched Rigidity & Damping: Manufactured from premium micro-grain solid tungsten carbide, the SCKCR2020K09 provides approximately 3x the stiffness of an equivalent steel shank. This dramatically reduces vibration, chatter, and tool deflection, enabling stable machining at higher depths of cut and longer overhangs.

Exceptional Surface Finish: The inherent stability of the solid carbide construction minimizes harmonic vibration, allowing you to produce superior internal surface finishes and hold tighter tolerances consistently, often eliminating secondary finishing operations.

Optimized for Deep Reach: The 20mm diameter (D1) and 200mm length (L1) make this bar an ideal choice for deep cavity work. The SCKCR (Clamp) style head provides excellent insert seating and clearance. Its strength allows for productive machining where steel bars would fail.

Precision Ground Shank & Geometry: Featuring a ground 20mm round shank with a precise 9mm hole depth (H) for the locking screw, this bar guarantees perfect concentricity and reliable, repeatable clamping in your CNC tool holder, essential for high-accuracy work.

Durable & Wear-Resistant: Tungsten carbide offers excellent resistance to abrasion and heat, ensuring longer tool life and more consistent performance over time compared to high-speed steel (HSS) or heavy-metal bars.

Technical Specifications:

Tool Type: Solid Tungsten Carbide Boring Bar

ISO Designation: SCKCR2020K09

Boring Style: SCKCR (90° Lead Angle, Clamp-type Top Lock)

Shank Diameter (D1): 20 mm

Total Length (L1): 200 mm

Cutting Depth: Dependent on insert size (See compatible inserts below)

Hole Depth (H): 9 mm

Coolant Through: Optional (depending on specific supplier variant)

Compatible Insert Recommendation:

Deep hole boring and internal turning

Machining high-tensile materials (e.g., stainless steels, Inconel, titanium, hardened steels)

High-precision bore finishing

Internal grooving and profiling

Operations where chatter and poor finish are problematic

| ▷SCKCR/L | |||||||||

| Designation | size / Размер | Inserts | Screw | Wrench | |||||

| H | W | L | ℓ | h | s | ||||

| Тип | Пластины | винт | Ключ | ||||||

| SCKCR/L2020K09 | 20 | 20 | 125 | 23 | 20 | 25 | CC**09T3** | M3.5X9 | T15 |

| SCKCR/L2525M09 | 25 | 25 | 150 | 23 | 25 | 32 | |||

| SCKCR/L2020K12 | 20 | 20 | 125 | 28 | 20 | 25 | CC**1204** | M5X12 | T20 |

| SCKCR/L2525M12 | 25 | 25 | 150 | 28 | 25 | 32 | |||

Company Information :

Ningbo SANHAN Alloy Material Co., Ltd. with years of experience in manufacture Turning Tool Holder ,Boring Bar ,Threading Tool holder , Grooving Tool Holder , Milling Tool Holder , Milling Cutter ,Drilling Tools , Threading Insert , Grooving Insert , Turning insert , Milling insert as well as their spare parts etc.

Located in Ningbo-China, a port city with developed industries. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including DMG Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly Welcome you to have a visit of our factory .

Turning Tool Holder Shipping:

| Port | Ningbo/Shanghai/Guangzhou/Hangzhou/Shenzhen/Xiamen | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory specializing in the production of external indexable turning tool holders,boring bars, threading

holders and grooving holders for CNC lathes and indexable milling cutters for CNC machine center as well as their

spare parts.

Q: Can we use our own logo or design?

A: Yes, we provide OEM and ODM

Q: What is your MOQ?

A: We have stock in stock for regular products, and we support a minimum order of one, and a minimum order of 20 non-standard products.

Q: How can I get some samples?

A: We are willing to provide you samples for testing after receiving the sample fee.

Q: Do you accept custom orders?

A: Of course, we are a professional manufacturer, and custom orders are what we are good at.

+86-19518052336

333 Liantang Road, Cidong Binhai Development Zone, Longshan Town, Cixi, Ningbo City, Zhejiang Province, China