English

EnglishCALL US

+86-19518052336

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

EnglishViews: 0 Author: Site Editor Publish Time: 2024-09-03 Origin: Site

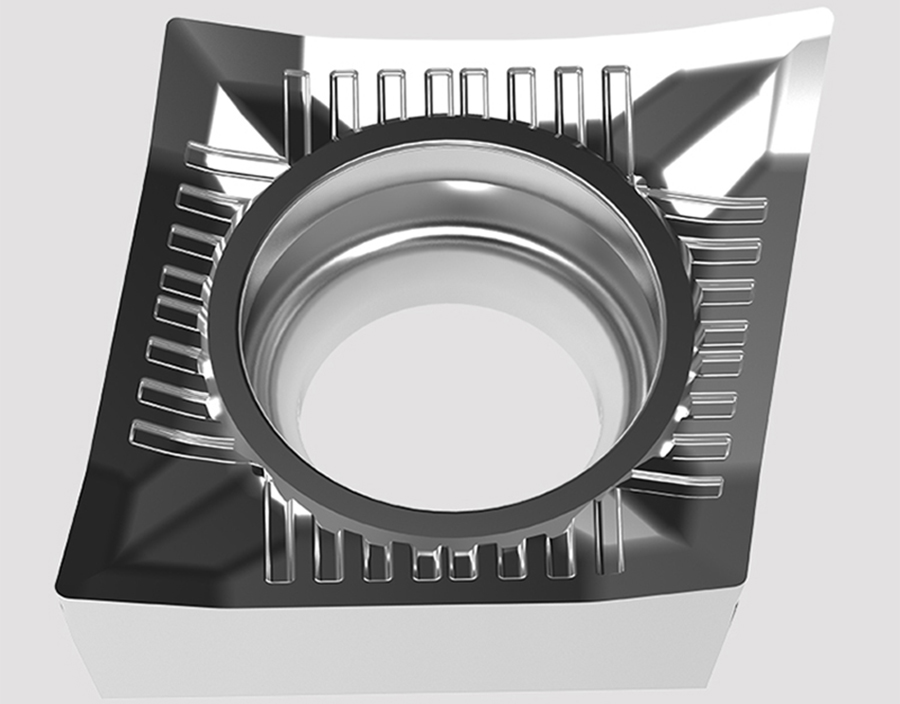

Tungsten carbide inserts are a vital component in manufacturing, enhancing the precision and efficiency of machining processes. Known for their exceptional hardness and durability, these inserts are integral to achieving accurate and consistent results in various industrial applications. This article explores the significance, benefits, and applications of tungsten carbide inserts in machining operations.

Tungsten carbide inserts are cutting tools made from a composite material of tungsten carbide and cobalt. This combination results in a dense, durable material that can withstand high temperatures and pressures, making it ideal for machining applications.

These inserts are typically used in turning, milling, and drilling operations, where they are employed to cut, shape, and finish materials like steel, aluminum, and other alloys. The use of tungsten carbide inserts allows for high precision and efficiency in machining processes, significantly improving product quality and reducing production costs.

The benefits of tungsten carbide inserts are significant:

Tungsten carbide inserts are renowned for their exceptional hardness, which makes them highly resistant to wear and tear. This durability translates to longer tool life, reducing the need for frequent replacements and maintenance.

These inserts provide superior cutting accuracy, essential for achieving tight tolerances in machining operations. The precision of tungsten carbide inserts ensures consistent and high-quality finishes on machined parts.

Tungsten carbide inserts are versatile and can be used in various machining applications, including turning, milling, and drilling. Their adaptability makes them suitable for a wide range of materials and machining conditions.

Using tungsten carbide inserts enhances machining efficiency by reducing cutting forces and improving cutting speeds. This efficiency leads to faster production times and increased productivity.

Tungsten carbide inserts are used across various industries for different applications:

In aerospace manufacturing, tungsten carbide inserts are used for machining complex components with high precision. Their ability to withstand the demanding conditions of aerospace applications makes them indispensable for producing parts like turbine blades and airframe structures.

Tungsten carbide inserts play a crucial role in automotive manufacturing, where they are used for machining engine components, transmission parts, and other critical automotive systems. Their durability and precision are essential for ensuring the reliability and performance of automotive parts.

In the medical field, tungsten carbide inserts are used to manufacture precision instruments and equipment. Their biocompatibility and ability to maintain sharp cutting edges make them ideal for producing surgical tools and diagnostic instruments.

Tungsten carbide inserts are also used in the oil and gas industry for drilling operations. Their hardness and wear resistance make them suitable for drilling through tough geological formations, ensuring efficient and effective drilling operations.

Selecting the appropriate tungsten carbide insert depends on several factors:

The type of material being machined influences the choice of tungsten carbide insert. Different grades and coatings are available to suit specific materials, ensuring optimal cutting performance and tool life.

The machining conditions, such as cutting speed, feed rate, and depth of cut, also impact the selection of tungsten carbide inserts. Choosing the right insert for the specific machining conditions is essential for achieving the desired results.

The geometry of the tungsten carbide insert, including its shape and size, plays a crucial role in its performance. Different geometries are designed for specific applications, and selecting the right one is vital for achieving optimal cutting results.

Tungsten carbide inserts are a critical component in modern machining operations, offering numerous benefits such as durability, precision, versatility, and efficiency. Their applications span various industries, including aerospace, automotive, medical, and oil and gas. Choosing the right tungsten carbide insert is essential for achieving optimal machining performance and results. As technology advances, tungsten carbide inserts continue to evolve, providing even greater capabilities and efficiencies in machining processes.

+86-19518052336

333 Liantang Road, Cidong Binhai Development Zone, Longshan Town, Cixi, Ningbo City, Zhejiang Province, China